Modern industry in order to fulfil the customer’s needs have to design new types of materials. These innovative materials have to meet an economic, ecological and elevated in use properties requirements. Unfortunately well-known and widely used materials do not meet industry expectations. That is why materials scientists are trying to find another way to fulfil these high demands of manufacturers, contractors and traders, without exposing them to excessive costs. A worldwide idea for creating and using new kinds of materials is one of the goals of the European Framework Program of Research and Innovation (2014-2020) – „Horizon 2020”. Exploiting the cross sector potential of nanotechnologies and advanced materials to drive competitiveness and sustainability is one of the program challenges. The development of nanotechnologies and advanced materials with a view to their use in several different applications and economic sectors is a problem that matches this theme. The nano materials can boost the competitiveness of European industry and make contributions to a sustainable economy. This includes also contributions to European culture and creativity through novel materials. Experimental research is widely used, however it is related to excessive costs due to sophisticated equipment that is required at this scale level.

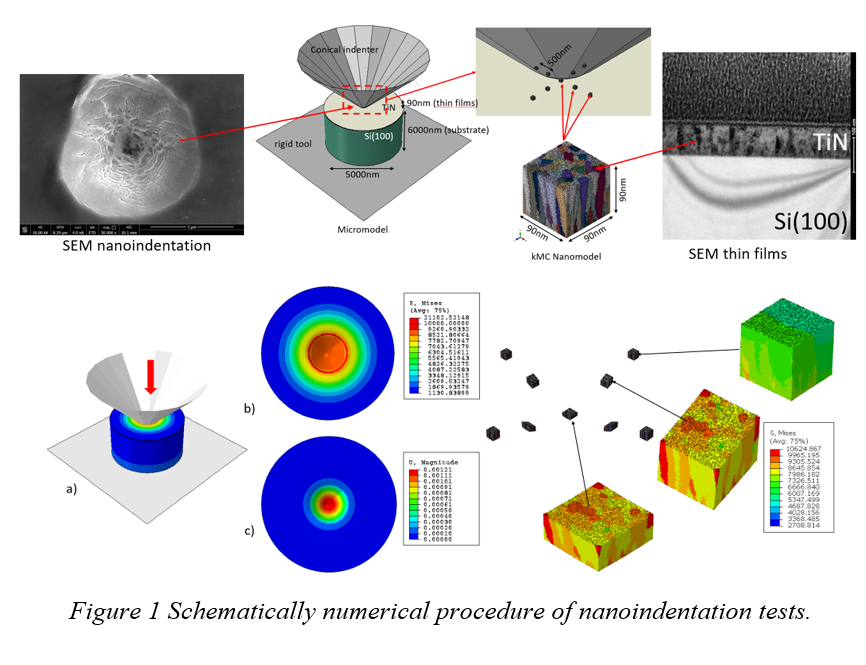

Thus, the main motivation of this project, was development of the multi scale numerical model capable to replicate material behavior during the nanoindentation test not only at the micro scale but also at nano scale level. The model provide basic knowledge about material response as a result of local deformation.

To support the simulation a numerical model based on the idea of digital material representation (DMR) was proposed. DMR allows during numerical investigation to take into account morphology and mechanical properties of every single structural elements in deposited structure. It can be summarized that the DMR approach makes it possible to obtain a completely virtual description of the deformation process and provides better quality of numerical simulations for material scientists. Investigated DMR was used to prepared multi scale nanoindentation models. Model at the micro scale was upgraded by nanoscale model where nanostructure features are taken into account (Figure 1). Digital models are often used in multi scale solutions that predict global material behaviour as well as can analyse microstructure changes during deformation in some critical/interesting locations, i.e. deformation response. Such an approach, which allows accurate replication of the material representation at the nano scale, is innovative and unique in the world, and its effect should bring the predicted behaviour of the material to its actual performance during deformation.